The importance of moisture control in animal feed production process

In the animal feed production process, the most important thing is to control the loss of water in the feed. Each of animal feed making line production process should adopt a scientific management method, find out the factors that affect the change of feed moisture, properly handle and solve them, and at the same time strengthen the production enterprise's refined management system to ensure the quality of each production process , fundamentally improve the economic efficiency of animal feed mill enterprises.

1. The importance of moisture control

Moisture control is the most important key link in the feed production and manufacturing process. It is necessary to combine the actual production situation and analyze the supervision and technical personnel to summarize the factors that promote the change of moisture content in each feed processing stage, such as moisture change and mixing in the crushing stage.

Factors such as phase moisture addition, steam moisture content, feed conditioning level, packaging quality management and other factors, so maintaining the accuracy of moisture detection is the most basic working principle for moisture content control. At the same time, we must also pay attention to the control of the water content of pellet feed. Because it is an important indicator to measure feed quality, the quantitative index directly affects the quality of pellet feed and the economic benefits of animal feed production enterprises. Therefore, it is very necessary to effectively control it.

The quality control personnel must fully understand the characteristics of the pellets. If they are not stored properly, they will easily become moldy and deteriorate, which will seriously reduce the content of nutrients. Moreover, the uneven moisture content will not only bring unnecessary losses to the feed processing enterprise, but also increase the quality of the products. The instability. It can be seen that the control of moisture content plays an important role in the production process of compound feed, which can not only ensure smoother production, but also reduce energy consumption and make pellet feed smoother and more uniform.

2. The specific principle of water loss or humidification of feed in the process of adding soil

Due to the complexity of the feed ingredients in the processing process, the way the water exists in the raw materials is also extremely complicated. Under normal circumstances, the chemically bound water in the feed can also be called product water, and the physical and chemically bound water is called adsorbed water or osmotic water. , And mechanically bound water is called free water, which is our common water quality such as capillary water, wetting water and interstitial water. Because the feed has the characteristics of moisture absorption and dehumidification, its internal moisture will change with the change of the external environment, and it is often in a state of moisture absorption or dehumidification.

When the moisture content of feed ingredients and finished products is in the range of 12% to 20%, the moisture characteristics are mainly capillary water and part of adsorbed water. Therefore, the feed is processed in spite of its moisture absorption and dehumidification. The process basically meets the processing standards, but from the perspective of the overall process, the feed moisture has suffered a certain loss, and the loss of water is basically mechanically bound water and part of physical and chemical bound water, and the loss rate is about 3%.

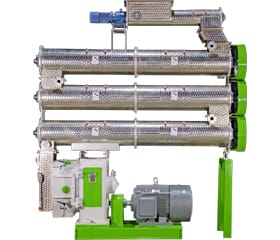

In addition, in the process of feed processing, the process of water decomposition and moisture absorption or moisture absorption will undergo a variety of processing procedures, such as conveying, crushing, tempering, homogenizing, granulating cooling, puffing drying, and suction. Among them, the moisture change is the largest in the processes of crushing, quenching and tempering homogenization, granulating cooling and puffing drying. Water decomposition and moisture absorption have the same principle.

When the feed is processed, if the medium air in the environment of the feed is very scarce, the water vapor on the feed surface will increase, and its water partial pressure will be greater than that of the air medium. This causes the moisture on the surface of the feed to automatically evaporate to the medium air. Conversely, when the water vapor pressure on the feed surface is lower than the partial pressure of water vapor inside the feed, the internal water will first transfer to the surface and then evaporate to the medium air. Therefore, no matter how the medium air in the environment of the feed changes, it will cause the loss of water, that is, the so-called feed dehumidification process.

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.